Cu Wire Evaluation

Integra has participated in various industry studies for Cu wire evaluation using different flows and inspection methodologies.

Through failure mode analysis and thorough understanding of physics, Integra can help assess potential Cu wire failures arising from component qualification, customer system manufacturing, and/or field failures.

Failure mechanisms that can be assessed include:

- Break mode understanding

- Implications of pad lifting

- Hidden micro-crack damages

- Die cracks

- Corrosion

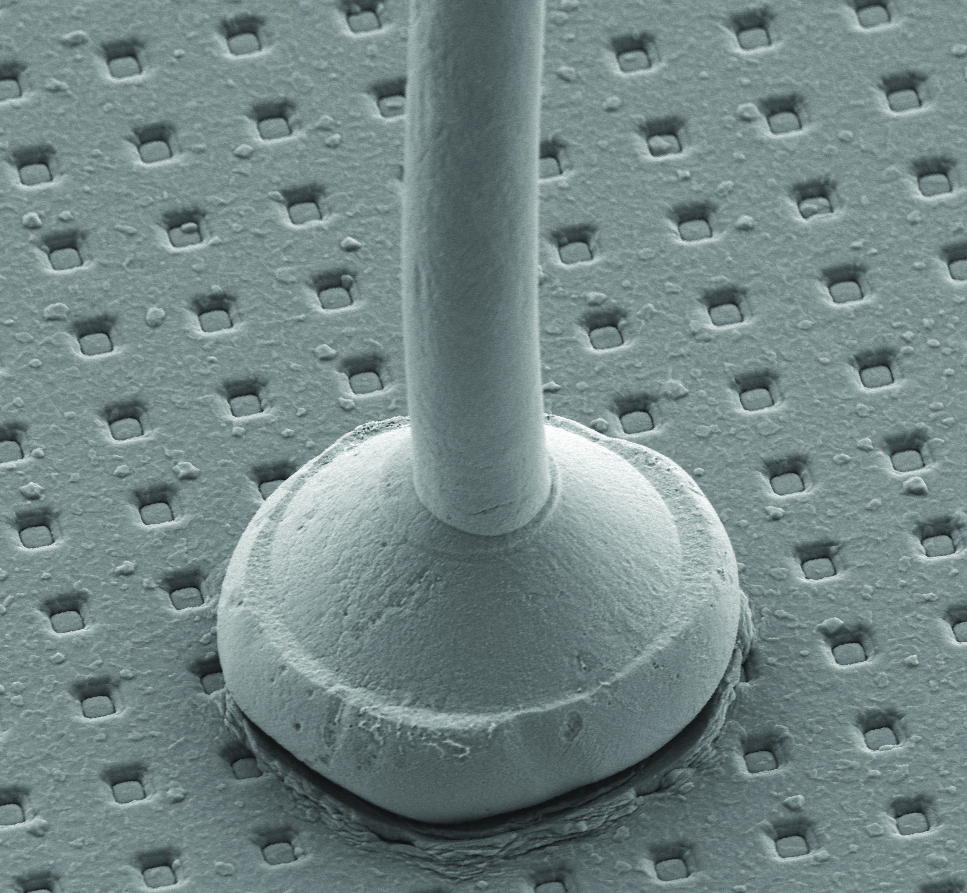

Integra offers a unique room ambient decapsulation process to minimize over-etching damage. The process includes the capability to etch and maintain complete integrity down to the ball attachment. Once the ball attachment is analyzed our process is capable of removing the ball attachment from the pad without destroying the metalized pad.

- Evaluation process flow includes control sample verification before actual sample decapsulation.

- Comprehensive reports with detailed photographs and data analysis are always provided.

Quality tests that can be performed for Cu wire evaluations include:

- Historical data comparison

- Ball diameter: detailed inspections per MIL-STD-883, M2010, condition A for Microcircuits and Hybrids and M2074 for Discrete devices

- Bond pull: MIL-STD-883, M2011 for Microcircuits and Hybrids and M2037 for Discrete semiconductors.

- IMC inspection using SEM per MIL-STD-883, M2010, condition A for Microcircuits and Hybrids and M2074 for Discrete devices

Extensive in-house reliability evaluation capability for Cu wire:

- Life test to study Cu wire wear out mechanisms

- Humidity tests with pre-conditioning

- Temp cycle

- High temp storage life

- Mechanical stresses

- Manufacturing process evaluation

In-House Equipment Includes:

- High resolution cameras

- Decapsulation stations

- Acoustic microscopes

- X-Ray

- SEM with EDX

- Cross sectioning equipment

- Vacuum bake

- Bond pull and bond shear equipment including precision gauges

- Reliability equipment for life test, high temp storage life, THB, HAST, temp cycle and vacuum bake